MITUTOYO - CNC Coordinate Measuring Machine MiSTAR 555| JSR GROUP

CNC Coordinate Measuring Machine MiSTAR 555

MiSTAR 555

Highly Environment-resistant Coordinate Measuring Machine,Allowing near-line or in-line inspection.

MiSTAR 555 is a CNC coordinate measuring machine conceived to be a “measuring machine for any environment”. Wide accuracy-guaranteed temperature range, environment-resistant absolute scale, and all-in-one space-saving design. With performance that sets it apart from conventional coordinate measuring machines, MiSTAR 555 will boost your productivity.

Environment

Making measurements in harsh shop floor environments possible.

With an environment-resistant absolute scale*1 and revamped body structure, MiSTAR 555 is a contamination-resistant coordinate measuring machine. Highly reliable as a result of real-time temperature compensation technology that guarantees accuracy over a wide temperature range, it delivers a length measurement error of just E0, MPE of 2.2 + 3L/1000 μm*2. MiSTAR 555 can be installed and operated next to machine tools on production lines.

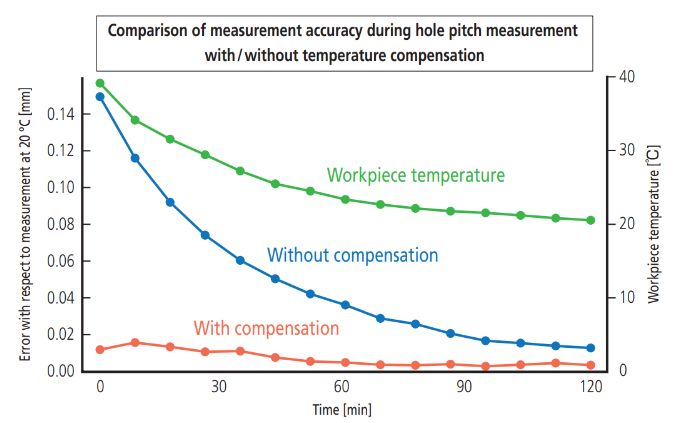

Wide accuracy-guaranteed temperature range

The accuracy-guaranteed temperature range of 10 ºC to 40 ºC is achieved as a result of body architecture designed with temperature traceability in mind. The real-time workpiece temperature compensation makes temperature stabilization unnecessary, allowing for installation in a wider range of temperatures than conventional coordinate measuring machines

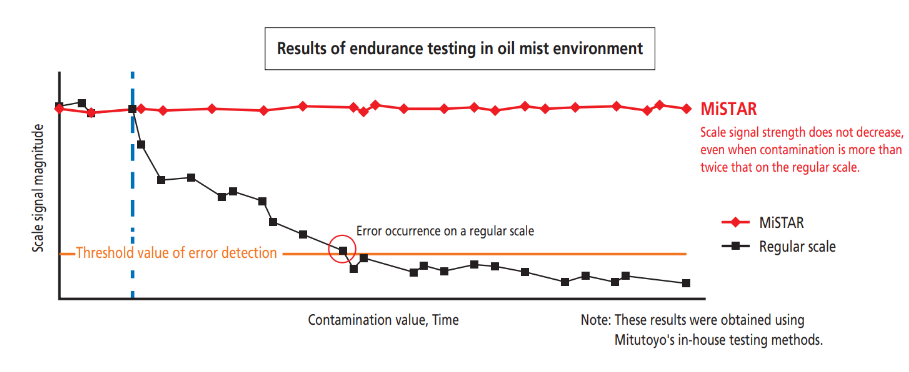

A Coordinate measuring machine resistant to contamination

A newly developed environment-resistant absolute scale having more than twice (in-house comparison), the contamination resistance of conventional models has been adopted, together with linear guides on the moving elements. The use of linear guides in place of air bearings eliminates the need for compressed air and eliminates contamination failure from the air source or the environment.

This CMM can go without maintenance for long periods, even when used on a shop floor subject to airborne oil mist.

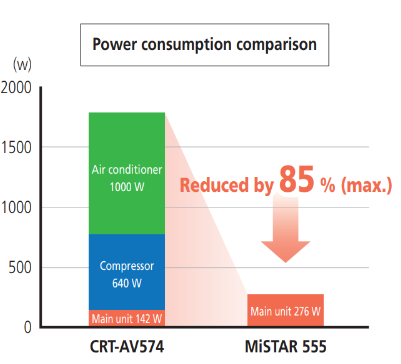

Energy-saving

With a wide accuracy-guaranteed temperature range and without the need for compressed air, MiSTAR 555 does not require a measuring room for its installation. This allows for substantial reduction in running costs compared with conventional coordinate measuring machines because it does not require a temperature controlled environment and air supply facilities

Usability

User-friendly design that reduces the operator’s workload.

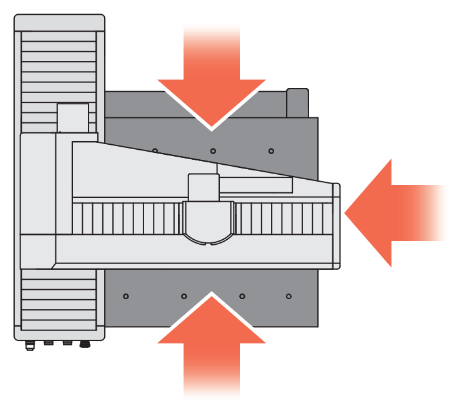

Cantilever architecture used to open the measurement area on three sides is the result of redesigning the measuring machine body design, starting from its material quality. Compared with a bridge or gantry design, it makes moving workpieces on and off the measuring table significantly easier. The user-friendliness of MiSTAR 555, enabled by being open on three sides, can be seen especially on shop floors and the like where workspace is often limited.

|

Improved efficiency with three-sided open architecture Three-sided open architecture while securing an ample measuring range of 570 (X) × 500 (Y) × 500 (Z) mm is very effective for moving workpieces on and off the measuring table. |

|

|

Simple, single button operation to start measuring MiSTAR 555 comes with the Quick Launcher, which enables simple and intuitive operation for easy part program execution. |

|

|

Positioning cannot be easier: Simply place the workpiece on the measuring table The optional clamping system and pallet receiver with positioning mechanism allow you to start measuring just by placing the workpiece on the measuring table, relieving you of the trouble of positioning the workpiece. |

|

Smart Factory

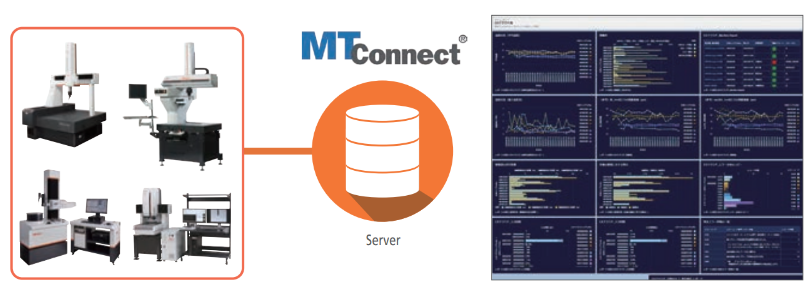

From status management to preventive maintenance. Kickstart your smart factory through visualization.

Allows you to monitor the operational status and condition of your coordinate measuring machine in real time, thereby realizing a non-stop system.

Status Monitor

Monitoring and logging of measuring machine operational status

Allows you to centrally monitor the operational status of coordinate measuring machines connected to a network, along with other measuring machines on the network. “Visualizing the operational status” allows you to reduce waste and improve the operating ratio of your production facilities.

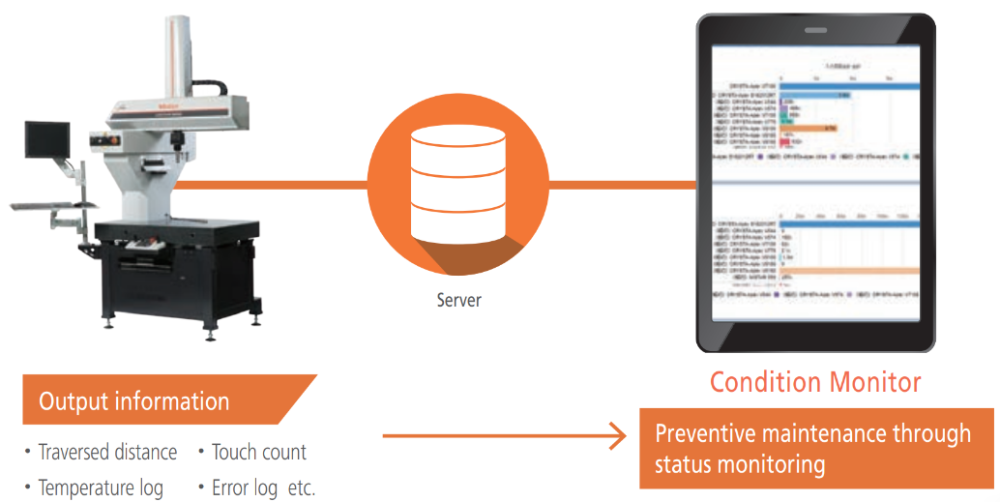

Condition Monitor

Preventive maintenance based on measuring machine status monitoring

“Visualization of status” through constant collection and accumulation of coordinate measuring machine status information, such as the probe touch count and total distance traversed by each moving element along each axis, helps to prevent sudden machine stoppages that could have been avoided by timely maintenance. Status monitoring enables you to achieve a non-stop production facility

Note: Please contact the nearest Mitutoyo sales office for adaptable countries and regions

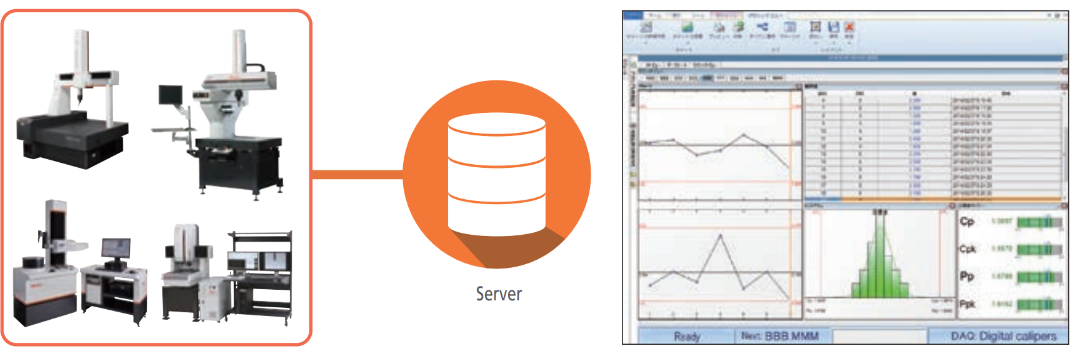

MeasurLink

Process management based on measurement data collection and analysis

“Visualization of quality” by collecting and accumulating measurement data from networked measuring machines, and then statistically processing this data on a server in real time helps to reduce defective products.

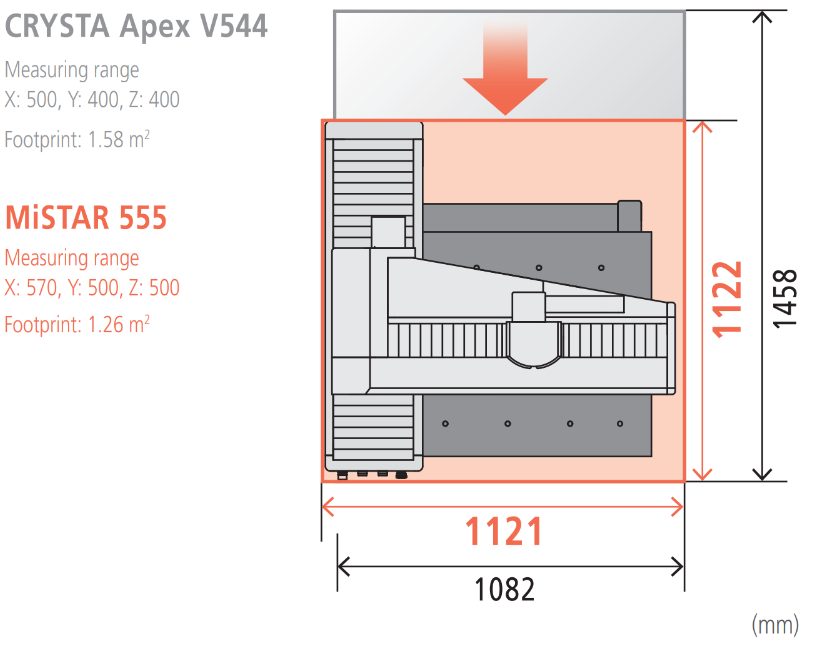

CompactFootprint-reducing all-in-one architecture broadens MiSTAR 555 options for installation sites. The storage cabinet for PC, machine controllers, etc., under the measuring table reduces the footprint by about 20 % when compared with that of other coordinate measuring machines with similar measuring range. |

Coordinate measuring machine footprint comparison

|

OptionParticularly effective to evaluate rotationally symmetrical parts like gears Rotary table This rotary table allows highly-accurate and efficient measurements of workpieces like rotationally symmetrical parts (gears, impellers and screw rotors). When used with a scanning probe, synchronized scanning measurements can be performed, enabling 4-axis scanning measurements. |

|

Softwareg

Application software that offers bothfunctionality and operability

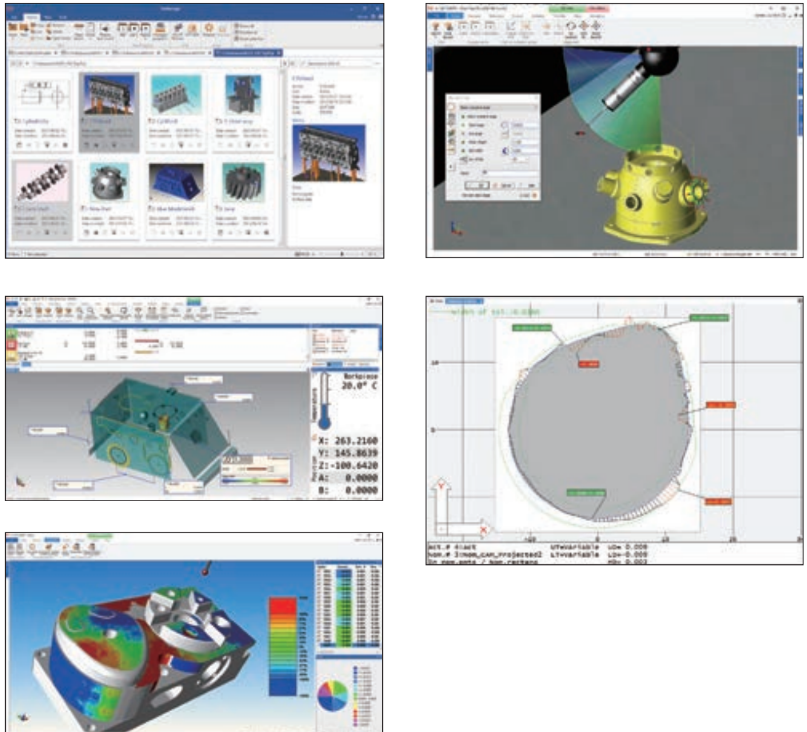

We offer an extensive lineup of application software for generating measurement programs automatically, CAD nominal/actual comparisons, user designed report templates, gear analysis, airfoil analysis, EDM inspection, and so on. From simple to complex measurements, these software applications can resolve any measurement issues that our customers may encounter

|

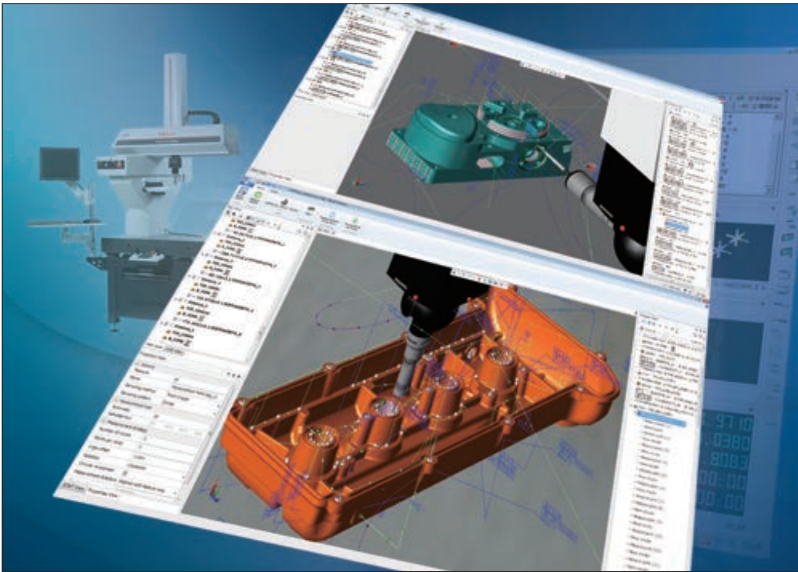

MCOSMOS Data Processing Software for CMMs A family of dedicated programs for coordinate measuring machines. A basic software with rich functionality and a wide variety of optional programs allows you to measure and analyze any workpiece.

|

MiCAT Planner Automatic Measurement Program Generation Software for CMMs Allows you to automatically generate measuring programs from the 3D CAD model. Ready-to-use programs are generated in the shortest time based on the minimum number of probe repositionings, number of probe changes, and shortest measurement path assessed by the optimization software.

|